Streamline your Supply Chain through Process Improvement

In today’s competitive marketplace, where time equates to money and customer expectations remain high, how to streamline supply chain management is no longer optional. Whether you run a trade company or a small enterprise, refining your processes and streamlining your operations can bring significant gains to your bottom line.

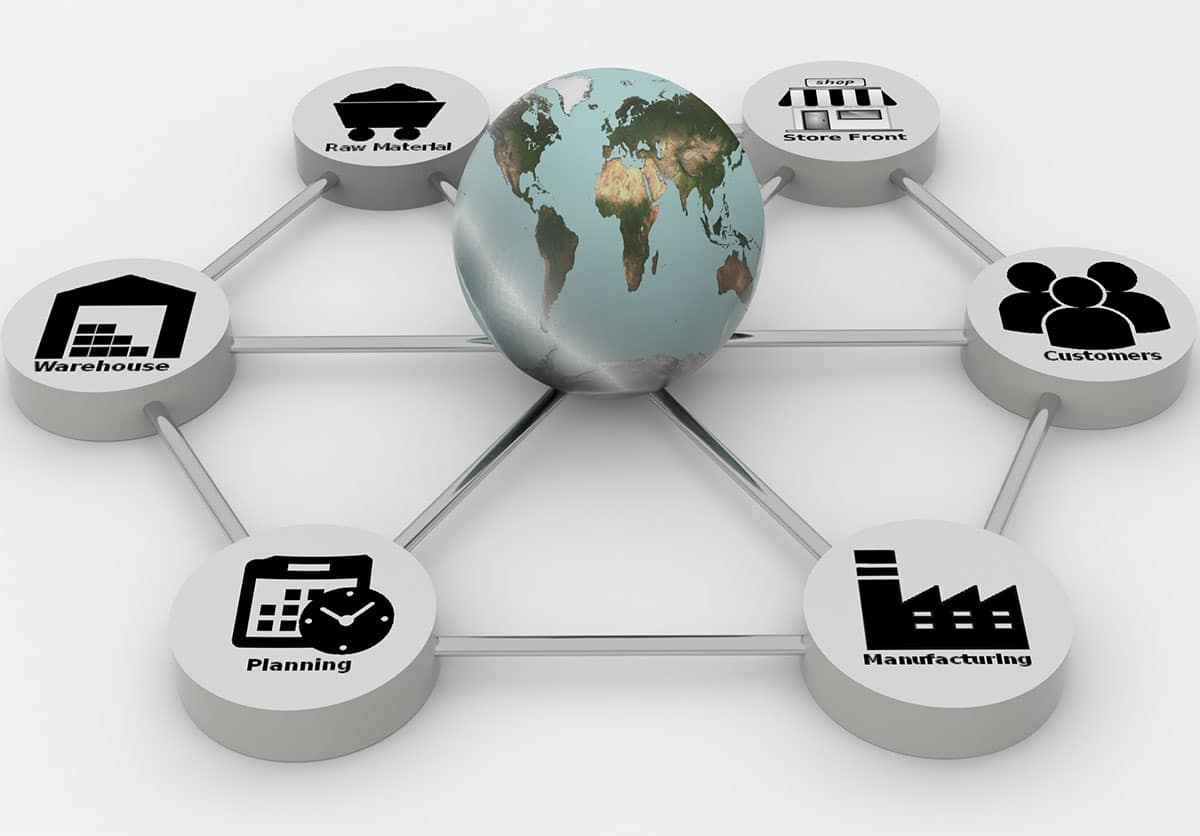

Before discussing process improvement steps, it helps to recall what a supply chain actually involves. It has the structure of a complex network beginning with raw material suppliers and continuing through manufacturers, distributors, retailers, and finally to the end consumer. These links are not isolated but connected components of a single system. Recognising how to streamline supply chain management turns this view from a chain into a strategic opportunity.

Process improvement means assessing your current practice and making it more efficient. It reduces waste, shortens timelines, and enhances performance. When small businesses focus on how to streamline supply chain management, they gain benefits across cost control, reliability, market agility, and customer satisfaction.

Understanding how to streamline supply chain management begins with ensuring that each part of the chain contributes rather than detracts. Mapping the flow from supplier through to delivery uncovers where delays or friction occur. These insights help you decide where improvements will have impact, and allow you to reallocate effort intelligently.

Another component of knowing how to streamline supply chain management involves identifying redundancies. Multiple touches, re-entries of data or duplicate checks may have grown up over time. Trimming these creates smoother progress and saves hours of work each week.

Focusing on how to streamline supply chain management also means improving communication. Whether through clear handovers, better scheduling or regular updates with partners, reliable information flow ensures that stock, data and decisions align.

When you learn how to streamline supply chain management, you also enhance your business culture. People pay more attention. Small changes add up to noticeable results over months. That shift—from firefighting to refinement—is how small firms gain traction and stay focused on growth.

- Understanding the Scope and Purpose

- Improving Efficiency Through Process Mapping

- Optimising Inventory and Lead Times

- Applying Intelligence and Automation

- Building Resilient Supplier Relationships

- Measuring Performance and Making Improvements

- Emphasising Customer Satisfaction

- Adapting to Market Shifts

- Taking Practical Steps

- The Cost of Doing Nothing

- Partnering for Long-Term Performance

Understanding the Scope and Purpose

Thoughtful supply chain management includes the planning, sourcing, manufacturing, warehousing, logistics, and delivery of goods. Understanding how to streamline supply chain management begins by knowing what each stage contributes to the flow of goods, information, and funds. Only by appreciating each function’s role can you know where real improvements can be made.

Every stage of your supply chain—from sourcing raw materials to delivering finished products—must contribute positively. This is the core of how to streamline supply chain management: ensuring that no part of your process drags down efficiency or causes waste. When each function adds value, your business gains stability, adaptability, and control.

Improving one area without considering the whole will not yield lasting benefit. Learning how to streamline supply chain management means you see how warehousing decisions affect delivery performance or how sourcing choices impact production timing. This integrated view allows you to align activities rather than optimise them in isolation.

Grasping how to streamline supply chain management also involves recognising that information must flow just as smoothly as products. Delayed or inaccurate data estimation can stall operations and undermine trust. Ensuring timely and accurate communication across stages supports both operational clarity and responsiveness.

In the end, each function’s contribution shapes your business rhythm. When you pursue how to streamline supply chain management, you build a system that is more efficient, responsive to change, and easier to manage. This results in a seamless flow that strengthens the whole enterprise.

Improving Efficiency Through Process Mapping

To understand how to streamline supply chain management, you must first map your existing processes. Start by tracing the full journey from procurement through to final delivery. Take note of every step, handover, and approval point. This exercise reveals where time is lost, tasks are duplicated, or mistakes commonly occur.

You may find that internal signoffs delay procurement or that logistics teams carry out overlapping duties without clear separation. These are not simply minor inefficiencies. Over time, they accumulate and impact customer service, cost control and team morale. Knowing how to streamline supply chain management means pinpointing these slowdowns with accuracy.

Process mapping highlights where the most energy is spent for the least return. It also shows you where systems do not communicate well or where staff must fill gaps manually. This visibility is critical when deciding what to fix first and how. When you have a full picture, you can focus change on the areas that cause the most friction.

Learning how to streamline supply chain management also involves looking at roles, not just tasks. Are the right people doing the right work? Could certain tasks be automated or shifted to different team members? Would changing the order of steps reduce lag time or prevent errors?

The answers to these questions come from the map. It shows you what is really happening—not just what you think is happening. That insight is the foundation of effective, lasting improvement. And it’s where true streamlining begins.

Optimising Inventory and Lead Times

Managing inventory is one of the most powerful levers when learning how to streamline supply chain management. Excess stock ties up cash that could be better used elsewhere, while stockouts mean lost sales and disappointed customers. The challenge is finding the right balance.

Tracking key metrics such as days inventory outstanding (DIO) reveals how long stock sits before it’s sold. This information helps you identify slow-moving items and adjust reorder points accordingly. When you know how to streamline supply chain management, you become more precise with stock levels rather than relying on guesswork or outdated habits.

Changing how and when you place orders is also essential. Frequent, smaller orders can reduce the need for storage space and allow you to respond more flexibly to changes in demand. This approach is especially helpful if lead times from your suppliers are short or if you operate in a fast-moving industry.

Reviewing supplier terms and agreements is another important step in learning how to streamline supply chain management. Negotiating shorter lead times or more flexible quantities can improve both responsiveness and cash flow. It means less money sitting on shelves and more working capital available for other areas of the business.

Refining your approach to inventory doesn’t require huge technology investments. Often, it comes down to better forecasting, smarter ordering, and more regular reviews of how your stock behaves. By embedding these practices into your routines, you reduce waste and free up funds that can drive growth—two outcomes at the heart of streamlining your supply chain.

Applying Intelligence and Automation

Technology plays a central role in understanding how to streamline supply chain management. Automating key steps like inventory control, order processing and logistics not only speeds things up, but also removes the errors and inconsistencies that slow businesses down. By linking your systems and processes through cloud platforms or integrated software, you gain real-time visibility into what’s happening across the chain.

Tracking stock levels, shipment progress and supplier performance becomes far easier. You spend less time chasing updates or correcting mistakes. This clarity allows you to act faster and make better decisions. When learning how to streamline supply chain management, small changes like automated reordering or digital invoice approvals can have a major impact.

Artificial intelligence is starting to shape supply chains in new ways. It helps predict customer demand based on seasonal trends or sales history. It can warn you of potential delays and even suggest different delivery routes if disruptions occur. Knowing how to streamline supply chain management now means staying open to these types of tools—even simple ones can bring significant time savings.

You don’t need to overhaul everything at once. Often, the best place to begin is with one slow area. Perhaps that’s how you receive stock or how you update customer delivery times. Apply automation there and expand as you see results. Streamlining through intelligence doesn’t mean complexity. It means giving your team the tools to move faster, with fewer mistakes, and more control.

Building Resilient Supplier Relationships

Your suppliers are more than vendors—they are partners in continuity. Transparency, clear communication and fair terms improve trust and responsiveness.

When you learn how to streamline supply chain management, strong supplier relationships give you priority in constraints, early warning of disruptions and often lower lead times.

Measuring Performance and Making Improvements

Performance data guides continuous improvement. Choose indicators such as on-time deliveries, stock turnover, order accuracy, and cost per unit. Review these regularly and adjust workflows, schedules and suppliers accordingly.

Applying how to streamline supply chain management means refining process instruments rather than assuming initial settings remain optimal forever.

Emphasising Customer Satisfaction

Supply chain reliability is not just internal. Customer trust relies on consistent delivery, accurate orders and clear communication.

When you focus on how to streamline supply chain management, customer loyalty increases because expectations are met more often and less reactively.

Adapting to Market Shifts

Efficient systems allow fast responses to changing trends or volumes. Whether adjusting production, customising products or launching promotions, agility stems from a streamlined supply chain.

Firms that investigate how to streamline supply chain management build flexibility into their operating rhythm—and thus remain competitive.

Taking Practical Steps

Start with mapping current workflows. Measure key metrics like inventory turnover and delivery accuracy. Apply simple automations where repetitious tasks remain. Reinforce supplier alignment with your business rhythm. Measure again—and repeat.

Each step reinforces how to streamline supply chain management as a practical framework, not just a phrase.

The Cost of Doing Nothing

Avoiding action carries a cost. Small businesses that overlook or delay efforts to improve their supply chain often experience compounding problems. Delays in deliveries become normal. Stock either runs out or piles up. Forecasting is guesswork, not planning. Admin becomes bloated. Every small error starts to feel bigger. The stress builds, and performance suffers.

This isn’t just about missed opportunities. It’s about real financial impact. Waste increases. Customer satisfaction declines. Staff morale drops under the pressure of inefficient systems. In the long run, doing nothing becomes far more expensive than making smart changes. Learning how to streamline supply chain management is not a luxury. It’s a necessary step for businesses that want to stay in control.

Those who commit to understanding how to streamline supply chain management often see results faster than expected. Even modest improvements—such as speeding up approvals or reducing duplicate tasks—can make a big difference. The key is starting.

Refining your processes opens the door to growth. It makes your business lighter on its feet, better equipped to adapt, and far less likely to be caught off guard by demand spikes or supplier issues. Investing time in how to streamline supply chain management now means less firefighting later and more space to plan, grow and lead.

The choice is simple: continue absorbing the cost of delay and disorder, or take deliberate steps toward a smarter, more resilient business.

Partnering for Long-Term Performance

Mastering how to streamline supply chain management is not something you have to tackle alone. Many business owners struggle to see the gaps when they are in the thick of daily operations. That’s where external support makes all the difference. The right partner can step in with clarity, tools, and a structured approach that moves your supply chain from reactive to reliable.

Working with an experienced advisor helps you map your entire process, from sourcing to delivery. Together, you can identify blockages, refine handovers, and apply the right systems to automate and simplify. You also gain access to proven methods and strategies that take years to develop internally. This is how to streamline supply chain management with confidence.

Support can be tailored to your size, your goals, and your current constraints. Whether it’s untangling inventory issues, improving supplier coordination or reducing unnecessary spend, an advisor brings order to complexity. They help train your team, introduce the right tools, and shift the culture towards continuous improvement.

When you invest in this partnership, you’re not just improving your systems. You are building long-term stability. You are protecting margins, preventing errors, and setting your business up for growth. And crucially, you are taking active steps to lead rather than react.

If you are ready to move past daily supply chaos and into a smoother, smarter way of working, Real Cloud Solutions is here to help. We guide small businesses through every step of how to streamline supply chain management with practical, hands-on support. From your first consultation, we focus on outcomes—not jargon or complexity.

Your time is valuable. Your resources are limited. Let us show you how to make both go further. Contact us today and start building a supply chain that works for you—not against you.